Mondelin tools have been on your job sites since 1952

Since 1952, we have continued the story of Roger Mondelin, to continue to design with and for craftsmen, tools that meet the needs of their sites.

Our brand

A FRENCH EQUIPMENT AND TOOLING BRAND CLOSE TO PROFESSIONALS

Since the creation of Mondelin in 1952, we have made every effort to preserve our know-how as a French tool manufacturer. We extend our ranges of tools and we innovate, while maintaining what is essential for us: the relationship that has always linked us to professionals, on their sites. The company originated in the mind of a visionary, but a realistic and rational visionary. Alongside professionals on a construction site since day one.

And since 1952, we have been inspired by the needs of professionals, their gestures, their daily work to adapt to their constraints and create the right tools.

ON YOUR SITES EVERY DAY

As Roger Mondelin did in 1952, we have chosen to continue to visit construction sites daily, in conjunction with our Research & Development team. To see, listen, understand new needs.

Also to have each tool tested and approved by different professionals before it is launched in production. Who knows better than a professional on their site if our tool is effective?

Within our R&D team, we improve our tools and equipment constantly.

More efficient, more comfortable, more ergonomic... We rethink and adapt materials, handles, blades, shapes, sizes... We also invent new, more functional and ingenious tools, which meet the real needs of professionals .

By maintaining what has been our strength since 1952: quality, robustness and durability.

IN 2022 WE TURNED 70.

We took this opportunity to renew our website (which you are reading now). We have changed our image, without transforming ourselves.

We asked ourselves questions about our values, our attitude... to confirm to ourselves that it had not changed in 70 years and that it was important to highlight it.

We wanted to put words on what makes us different.

And it seemed obvious to us that our greatest strength were our professionals.

For 70 years, there has always been a professional behind the design of each of our tools.

Then we adopted a “brand signature”, which sums up 70 years of daily work: Inspired by your sites.

THE EVOLUTION OF THE LOGOTYPE

In 1952, the company's first logo design were the initials of Roger Mondelin, which were then quickly changed to a windmill.

As Mondelin company was created rue du Moulin-à-Vent in Roanne (42-Loire, France). (Windmill Road)

OUR HISTORY SINCE ROGER MONDELIN

IN 1952, ROGER MONDELIN CREATED HIS COMPANY.

He had skills in making models. That is the traditional profession of making wooden "models" for foundry parts. It brings together carpentry, sculpture, woodturning and metallurgy.

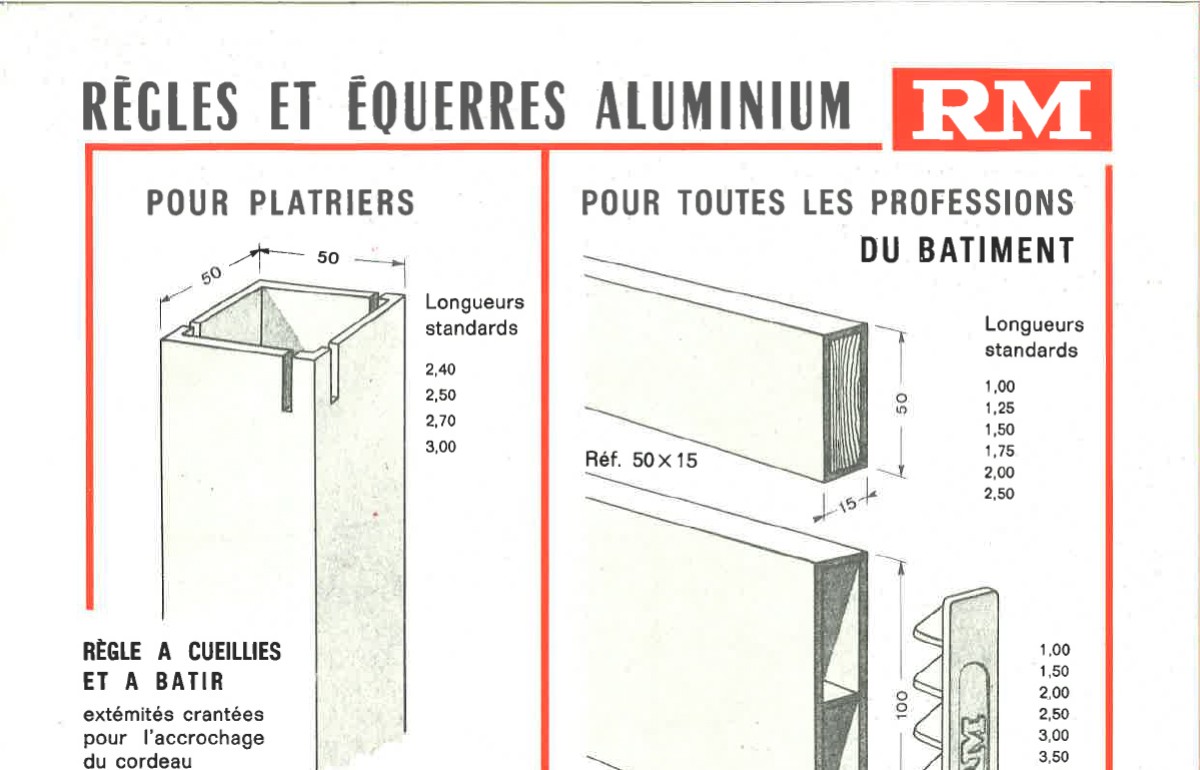

Then, with the same high standards and precision Roger Mondelin designed his first hand tools and equipment for building professionals : wooden floats, wallpapering tables, plasterer's tools.

Thanks to its quality tools and its know-how the family business Mondelin expanded to become a SME in the 1960s.

THE 1960s, A TURNING POINT IN THE HISTORY OF MONDELIN

In 1959, Roger Mondelin recruited Gérard Nurain to manage manufacturing in the factory. Next he recruited Jean Granet, the company's first “ sales representative”. The trio then mastered ideas, manufacturing and marketing, to expand the company throughout France.

Roger Mondelin could continue to spend a lot of time on construction sites talking to professionals and so he could understand their real needs. The bond he maintained with professionals remains one of our fundamental values today.

1969, MONDELIN SET UP IN AMBIERLE

Our present production site was founded few kilometers from Roanne.

The Ambierle plant is gradually being developed.

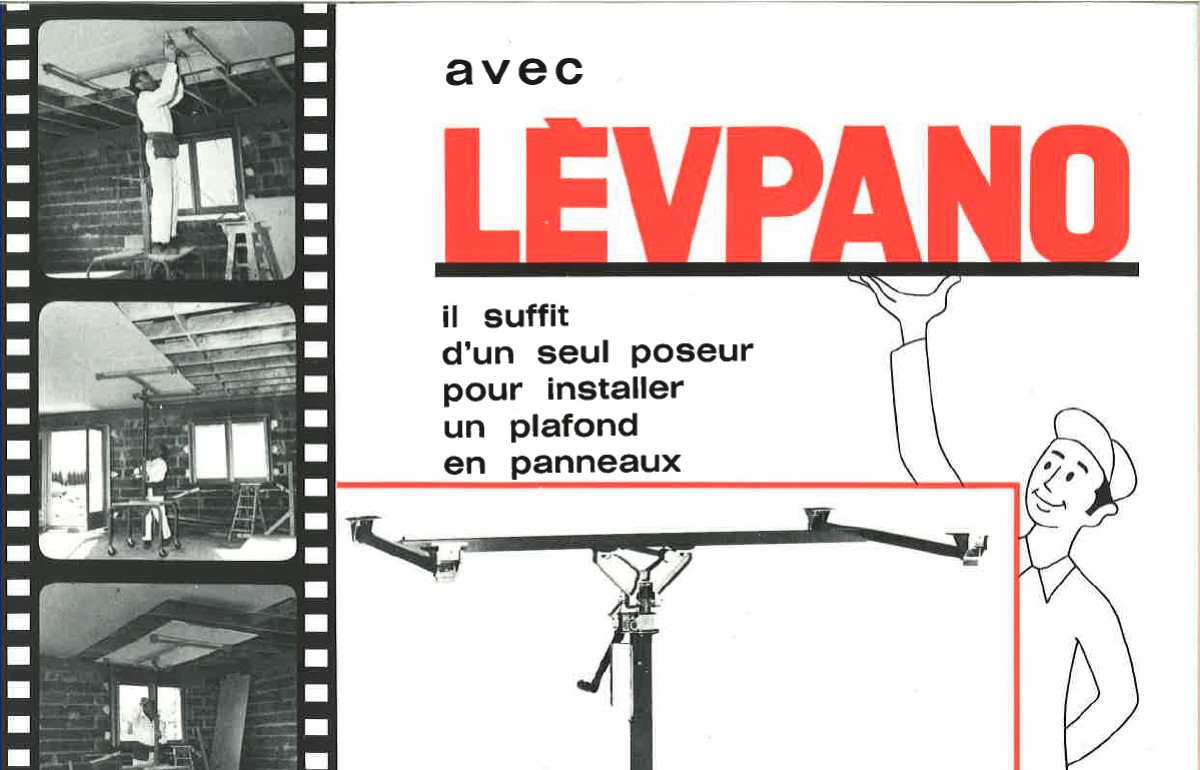

1976, ROGER MONDELIN CREATES THE FIRST LEVPANO® drywall lift

The concept of a drywall lift, which allows the plasterer to install plasterboard on the ceiling alone and in complete safety, only existed in the United States.

In 1976, this innovation created a real revolution in Europe for plasterers.

With Levpano®, “one installer is enough to install a plasterboard on the ceiling”. An amazing selling point from that time!

As soon as it was marketed, Levpano® met with real success with professionals and the company filed its first patent in 1989.

Since then, our Research & Development team has been constantly working on the range of Levpano® professional drywall lifts, improving the products and regularly filing patents.

A new version of Levpano® is marketed every 2 years on average, which allows our Mondelin company to confirm and maintain its leading position in the market.

MADE IN AMBIERLE, IN OUR FACTORY

SINCE 1952, WE HAVE BEEN A FRENCH TOOLING COMPANY.

More than "Made in France", we would like to add that our tools have been made "Made in Ambierle", in our Mondelin factory since 1969. At the factory there work are 3 strategic trades : metal work, wood work and plastic injection.

We choose to control each step in the manufacture of a Mondelin tool.

“Metalworking, carpentry and plastic injection, each trade is a supplier to the other in our factory. We are totally autonomous, from the whole tree trunk to the injection of our bi-material handles, assembly, etc.

We have created a complete, efficient ecosystem that can adapt.

This allows us to control every detail and modify a tool as soon as we wish.

We even recently added a cardboard folding line to manufacture our own packaging.

Our customers and our planet were calling for less plastic, so it was obvious to us that we should organize it ourselves. At Mondelin, we go all the way!”

Christophe Valette, director of the Mondelin factory in Ambierle (42).

METAL, MAJOR KNOW-HOW OF THE MONDELIN FACTORY

Shaping and cutting of tubes, steel and stainless steel strips, aluminum bending, laser cutting, degreasing, bending… our Mondelin factory masters all techniques, works with all thicknesses and shapes for the manufacture of our tools.

Our trowel blades and knives, our steel or aluminum tools, our Levpano®, our stepladders...

“Metal is the key material in our factory. We master quite technical blade finishes and, above all, we work with high quality raw materials. Simply because we are looking for reliable, robust tools that meet the needs of our professional customers.

Seeing a customer sand a new knife blade because it catches is unthinkable! In our company, we pay attention to finishing, rounding edges just enough. Because we tested the perfect application of the coating on the construction sites."

Denis Narelli, R&D and locksmith workshop manager at the Mondelin factory in Ambierle (42).

WOOD AND JOINERY

Cutting of wooden logs, cutting, machining, mouldings… all the stages of carpentry are present in our Ambierle factory. Even including recycling of offcuts and shavings to supply our biomass boiler.

We manufacture our Mondelin tool handles, our trowels, the beams of the trestles, the boards of the platforms of our stepladders or Levpano®. Wood species are chosen for their mechanical resistance. Beech for hardness, resistance. The exotic Ayous for lightness and its hydrophobic character or its ability to stay flat and retain its dimensions over time, etc.

“Wood is a material like no other. It is living matter. Performance cannot be predicted in advance. Watching nearly entire trees arrive at the factory, we don't know how many knots we will find, what the condition of the wood is, how many perfect floats we will produce with it.

But it is such a beautiful material, light, pleasant to the touch, naturally anti-vibration. I am happy that it regains its letters of nobility through its environmental qualities."

Pascal Maisonhaute, head of the carpentry division of the Mondelin factory in Ambierle (42).

PLASTIC INJECTION

Mondelin's historic know-how since the early 1980s, the plastic injection workshop was completely redesigned and modernized in 2016. It has since incorporated new injection molding machines and manufactures most of our tool handles.

The machine park allows the design of small parts, Levpano® components or our stepladders; also the manufacture of our knife handles and trowels; and also larger tools such as buckets, troughs, trowels, Projoint®…

“From mold design to bi-material injection, we control the entire assembly line in Ambierle. We adapt the material, the shapes, the injection techniques such as gas or bi-material injection to the needs of the tool to provide more comfort, better handling, resistance...

For each tool manufactured at Mondelin, we are guided by its use.

And plastic allows very precise modifications. It is an essential material, which can be part of our environmental approach. We manage to use 72% recycled materials. By purchasing or by upgrading our own offcuts, here in Ambierle”.

Alexis Ducard, manager of the plastic injection division at the Mondelin factory in Ambierle (42).